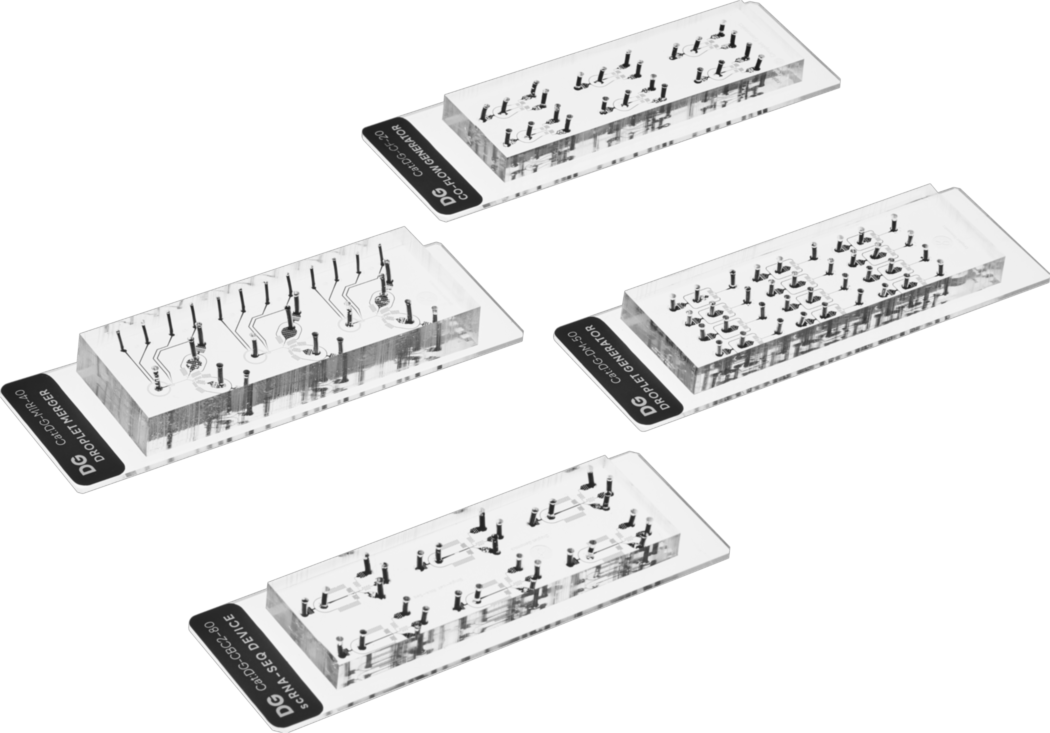

Microfluidic Chip Types

Droplet Generation Chips

Used for monodisperse water/oil droplet generation. Each device has one inlet for the aqueous phase and one inlet for the oil phase. Choose the droplet size that best fits your experimental needs, from 20−25µm to 55-65µm. Each chip has 6 or more microfluidic devices.

Droplet Splitting Chips

Used to passively split one droplet population into two or more via mechanical manipulation. Divide droplets into smaller ones to optimize reaction conditions or reduce sample consumption Different designs are available for various applications. Each chip has 6 microfluidic devices.

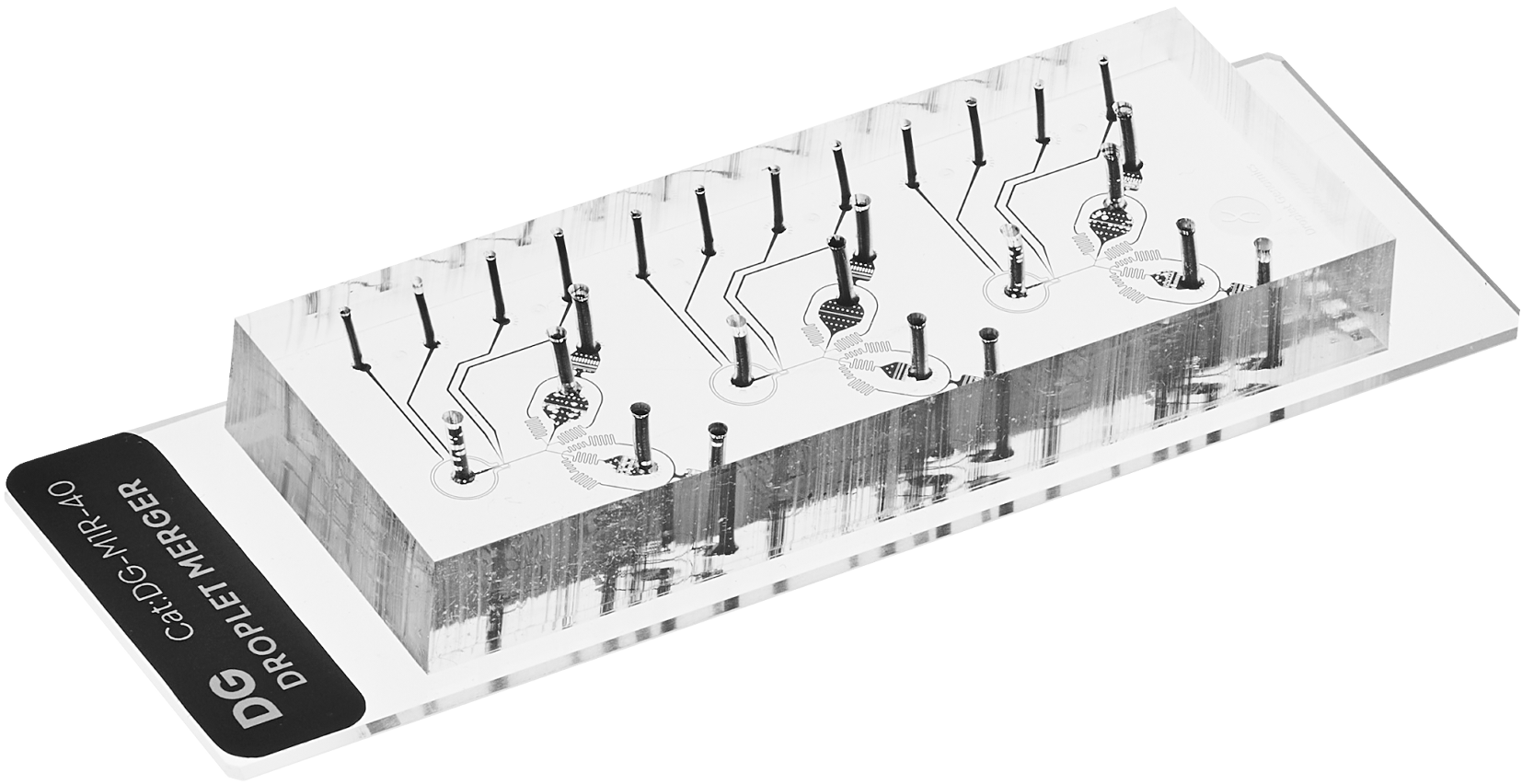

Droplet Merging Chips

Used to actively merge two different droplet populations for high-volumetric reagent addition. Droplet manipulation is enabled by a high-voltage electric field. Different designs are available for various applications. Each chip has 3 microfluidic devices.

Picoinjection Chips

Used to actively add reagents into the droplets. Picoinjection is ideal for easy sequential and combinatorial addition of reagents. Each device has one emulsion reinjection inlet and one inlet for the additional reagents. Each chip has 3 microfluidic devices.

Cell Barcoding Chips

Used for single-cell transcriptome barcoding experiments. Depending on product selected, the cell barcoding chips use either three or four channels to combine two or three aqueous phases with an inert oil phase to create a monodisperse emulsion. Each chip has 6 individual devices.

Droplet Sorting Chips

Used to actively select a specific droplet population, based on fluorescence signal, for high-throughput fluorescence-activated droplet sorting. Each device has one emulsion reinjection inlet and two outlets. Each chip has 3 microfluidic devices.